The MeasurLink quality management software from Mitutoyo delivers complete support for your manufacturing process control system. MeasurLink 9 offers online data collection, SPC charts and analysis, and quality control / supervisor reports and alerts for your entire manufacturing system — all in real time. Designed to create a quality information-sharing system for integrated networks, MeasurLink includes a comprehensive data collection metrology solution for your company.

Collect, Analyze, Monitor and Manage Data in Real Time

Acquire Data from Virtually Any Measuring Device

MeasurLink real-time standard functions as a data acquisition clearinghouse by enabling you to connect and acquire data from virtually any measuring device. It supports the full range of metrology technology including calipers, micrometers, indicators, CMMs, vision systems and more.

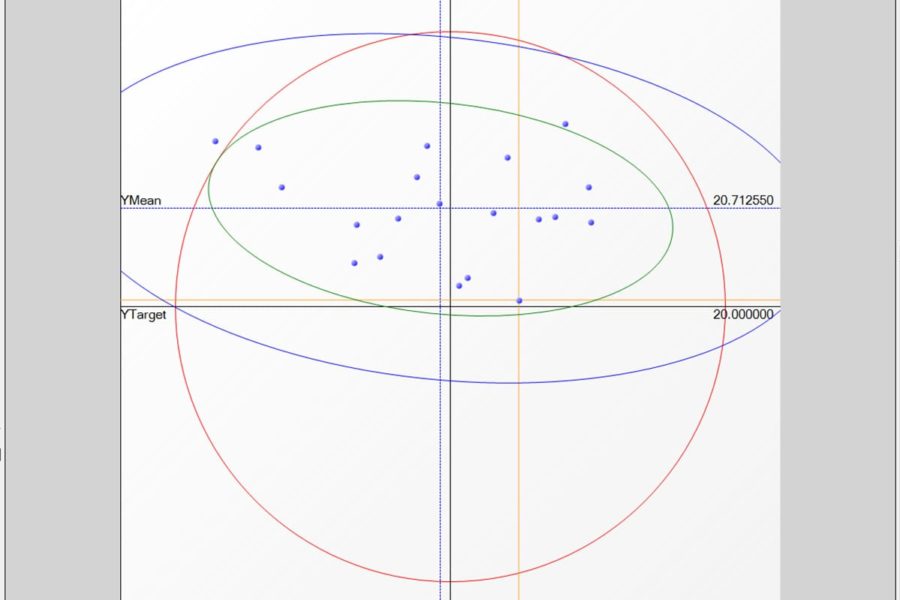

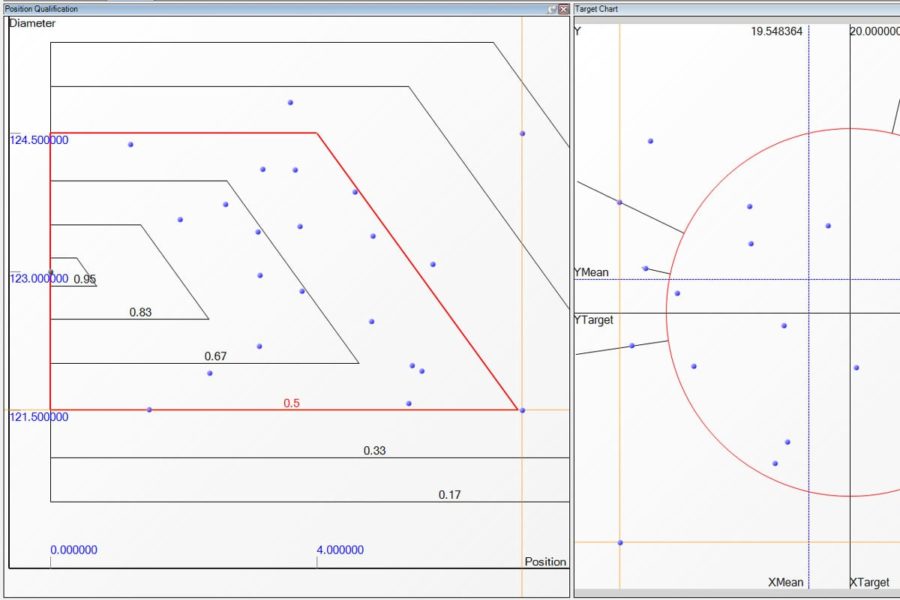

Chart True Position

MeasurLink supports true position charting and positional tolerance handling. This functionality allows related characteristics to be grouped together, generating visual representations of true position relative to a reference dimension.

Determine Bonus Values

MeasurLink 9 determines bonus values and even calculates capability values for a position characteristic when material condition information is provided for the reference value.

MeasurLink

* Interface to third-party equipment also available.

MeasurLink detects and displays patterns along with additional statistical information. Many patterns are displayed on SPC charts, including:

- Cycles

- Trends

- Freaks

- Mixtures

- Grouping or "bunching" of measurements

- Gradual change in level

- Sudden shift in level

- Instability (abnormally large fluctuations)

- Stratification (abnormally small fluctuations)

- Interactions (two or more variables acting together)

- Systematic variation

- Tendency of one chart to follow another

A Continued Commitment to Innovation

Highly skilled Mitutoyo developers and engineers continually update and improve Mitutoyo’s MeasurLink quality control management software in an international network of Mitutoyo research and development labs.

Mitutoyo’s CTLabs and Micro Encoder Inc. are part of an international network of Mitutoyo research and development facilities that are developing breakthrough technologies like MeasurLink, as well as other sophisticated metrology software such as Mitutoyo MCOSMOS® and MiCATTM Planner.